Release time:2022-03-31

Now most people are familiar with plastic shells, because there are all kinds of plastic shells in people's life, but we only know that the application field of plastic shells is very common.

But I don't know how the plastic shell is processed. So, in order to let more and more people understand how plastic shells are processed, let's take a look at the processing process of plastic shells today.

Let us know how to process plastic shell.

In the case of processing the plastic shell first, what we need to do is to prepare the corresponding plastic shell materials, which is also the most basic and important step. Because the plastic shell materials are intended to immediately endanger the finished products of the plastic shell, we must prepare high-quality plastic shell materials in advance.

Let's introduce the preparation of relevant materials here in advance. Next, let's talk about the solution for the material in the case of plastic shell processing. Since the plastic shell material has been prepared, it is necessary to solve the problem of plastic shell material in order to process and fully dry the moisture in the plastic shell material. This step is called mixed drying. Its significance is that the plastic shell can prevent vacuum pump bubbles and crazes on the surface after production and processing.

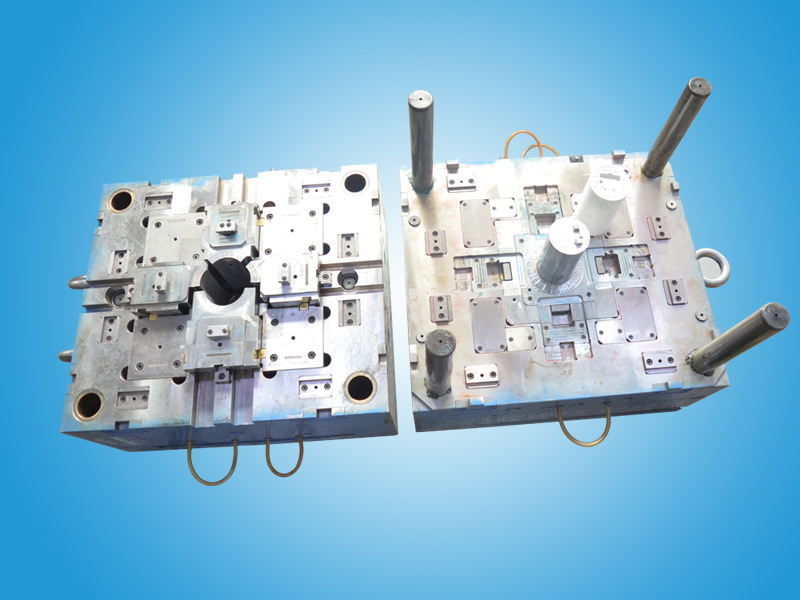

After the materials are prepared, we should make preparations for the injection molding stage of plastic shell processing in advance. At this stage, we should first prepare the corresponding mold shell and check whether the mold shell can meet your processing specifications, so as to ensure that the versatility of the plastic shell has no shortcomings. During injection molding, temperature must be a critical stage, which determines whether the plastic shell can be successfully manufactured. Because the temperature is too high, the material will become wear-resistant, and the material will fail, but the temperature is too low to be injection molded. Therefore, we must control the processing temperature of the plastic shell.

After the injection molding stage, only the plastic shell needs to be inspected for quality, and then it can be packaged and launched.