Release time:2022-04-06

Power supply plastic shell is very common in our life now. All walks of life are gradually inseparable from the use of power supply plastic shell, so power supply plastic shell has become more and more important in our life. There are many problems worthy of our attention in the production process, and many friends do not know how to deal with some problems in the production of power supply plastic shell, Now let's talk in detail about what problems need to be dealt with in the production of plastic shell of power supply.

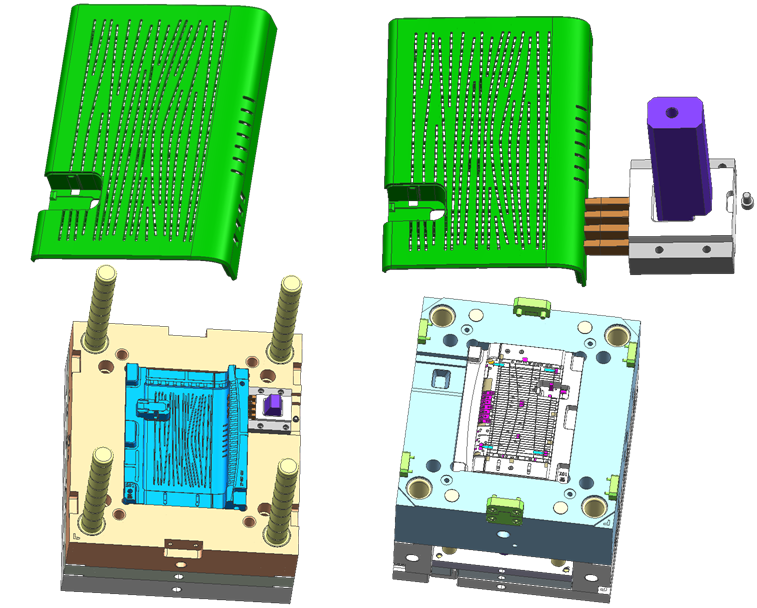

There are many problems that need to be dealt with in the production of the plastic shell of the power supply. The first problem to be dealt with is the problem handling in the preparation work. Obviously, a little carelessness in the preparation of materials and molds will cause problems in the quality of the plastic shell of the power supply, and the quality of the plastic shell of the power supply after processing cannot be guaranteed, so the quality problems must be properly handled when preparing materials. However, the preparation size of the mold also needs to be handled by us. There should be no deviation, otherwise the internal stress of the plastic shell of the power supply can not be handled well, and the inner wall thickness of the plastic shell of the power supply will be a problem. Therefore, we should deal with these two problems when producing the plastic shell of the power supply.

After all the preparations are handled, we can't directly inject the material of the plastic shell of the power supply, because in terms of materials, we also need to deal with the moisture inside to let the moisture evaporate fully, so as to remove the vacuum bubble problem after the plastic shell of the power supply is formed.

Finally, during the injection molding of the plastic shell of the power supply, we still need to deal with the problem of temperature control. The temperature control during the injection molding is very important, which determines whether the plastic shell of the power supply can be completely molded, so the temperature is best controlled between 240 ° -320 °.

These are the problems that need to be solved in the production of plastic shell of power supply. I hope you can better solve these problems in the future.