塑胶外壳由于其有很强的绝缘性强,而广泛应用于生活的方方面面。如果这些物品是由金属制成的,则绝缘性能就很差。还需要一个保护层。在这种情况下,与金属材料相比,塑胶材料不只价格便宜,确保安全,而且具有很强的绝缘性能。塑胶外壳的生产厂家在生产加工过程中需要注意什么? 一、工件的成型周期 这包括塑胶时间和产品……

MORE

医疗器械外壳吸塑加工是一项精细的技术活动,对产品的外观、颜色、尺寸、内置紧固件、螺孔等公差要求很高。用我们行业的话说,用注塑标准和吸塑是一个很矛盾的问题。所以对于厂商来看,确实需要丰富的实践经验和大量的知识。在此基础上,可以更好地利用该技术加工出符合客户需求的医疗器械外壳,为各类医疗设备提供稳定的外壳。 ……

MORE

如何处理塑胶外壳加工中的模具结垢?我坚信,在进行塑胶外壳的生产和加工的时候,我们都会被一个难题所迷惑,随之而来的就是解决塑胶外壳的结垢问题。很多朋友也知道一些关于塑胶外壳模具结垢的解决方法。让我们从塑胶外壳上去除更多的模具结垢和磨料,让我们提前准备好信息内容,希望能够更加容易的解决塑胶外壳的模具结垢的问题。 ……

MORE

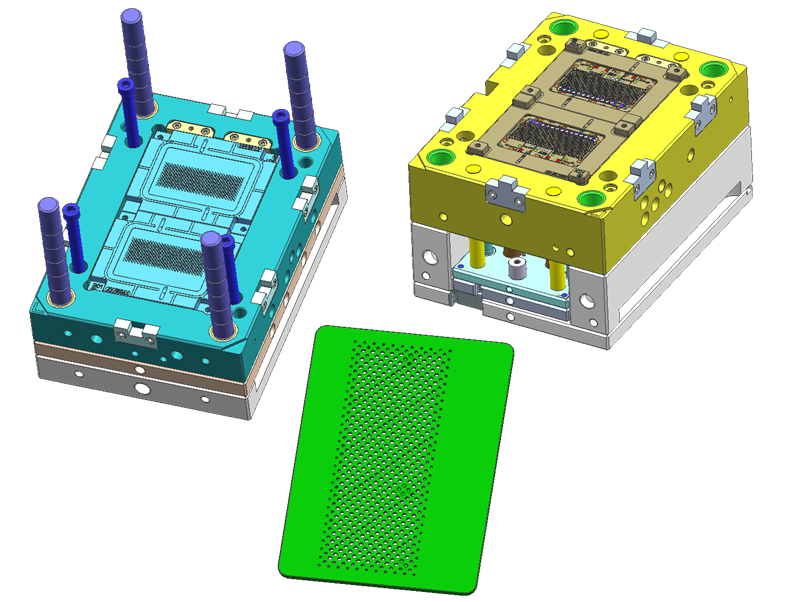

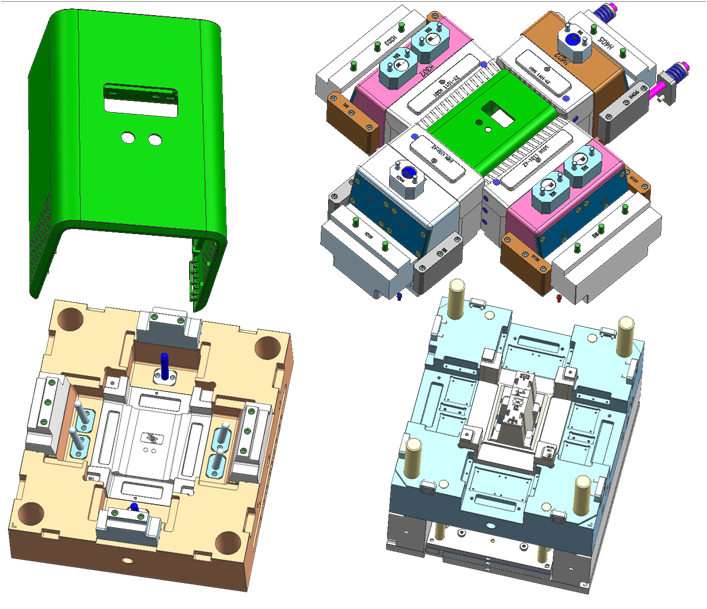

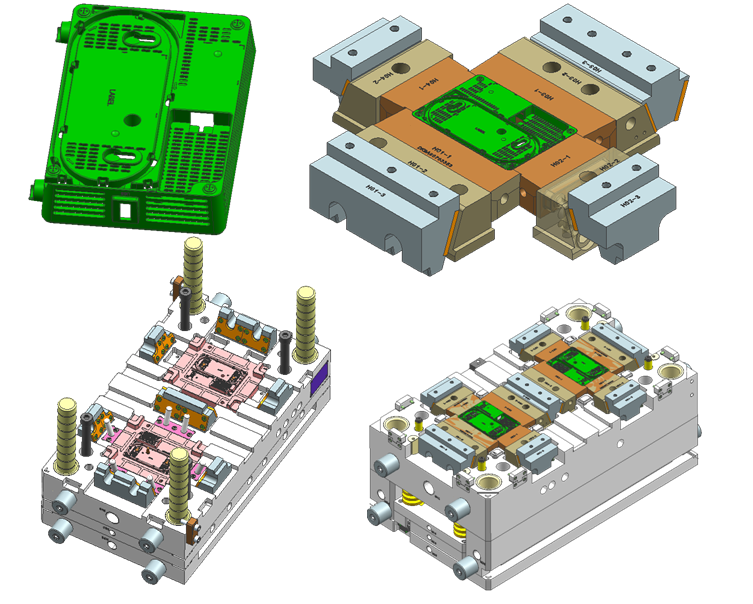

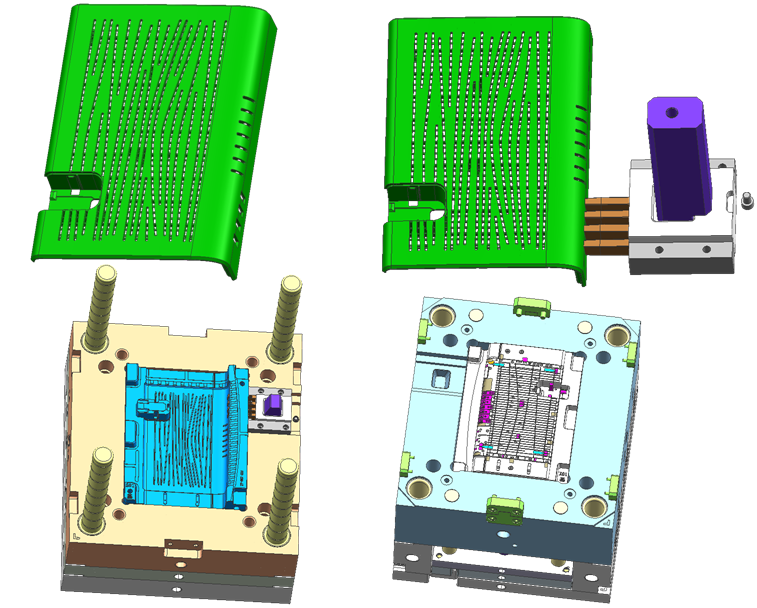

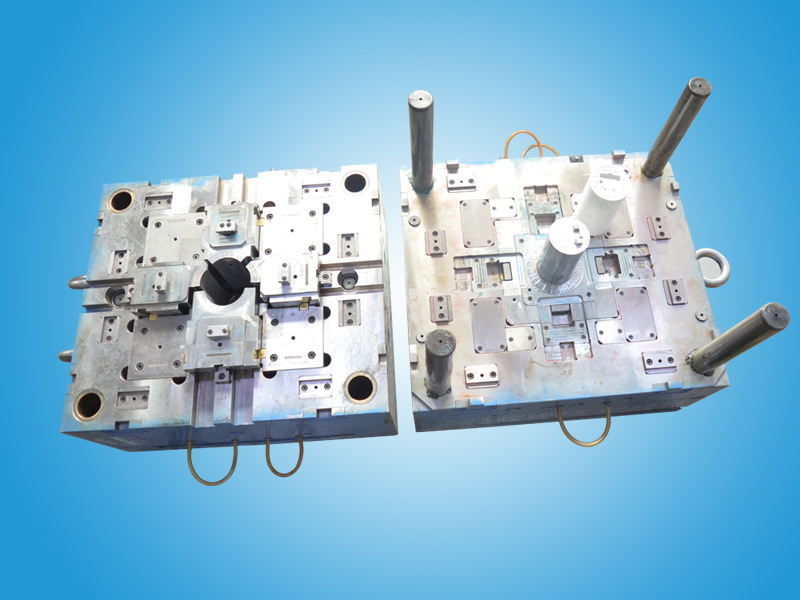

Mold processing refers to the processing of forming and blank making tools, in addition to shear molds and die-cutting molds. So what are the characteristics of mold processing? 1. High machining accuracy is required. A pair of molds is generally composed of a female mold, a male mold an…… MORE

In recent years, the plastic shell of switching power supply has been widely used. The emergence of the plastic shell of switching power supply makes it more safe for everyone to use the plastic shell of switching power supply. The plastic shell of switching power supply is a very useful…… MORE

The power supply plastic shell has been quite active in our life. Take our common mobile phone charger shell as an example, its main material is made of plastic. A very common feature is that it plays an insulating role. For example, our notebook power supply plastic shell or electric ve…… MORE

Injection molding is a specific cycle. There are five factors that affect injection molding: temperature, speed, pressure, position and time. These five process factors determine the quality of injection molding. The quality problems often encountered in injection molding are mostly caus…… MORE

The accuracy of plastic injection mold processing determines the accuracy of plastic parts, so it is very important to control the accuracy of plastic injection mold processing. So how should we control the accuracy in the process of mold processing? 1. Optimize the processing technology…… MORE

1、 Light weight led waterproof power supply plastic shell is a relatively light material, with a relative density of 0.90~2.2. Obviously, can the plastic shell of LED waterproof power supply float to the water? In particular, the foamed led waterproof power supply plastic shell has micro…… MORE

At present, the proportion of plastic mold in the whole mold industry is about 30%, and the proportion in mold import and export is as high as 50-70%. In recent years, plastic molds have developed rapidly in China, and plastic products are more and more widely used, providing a broad mar…… MORE

In the process of processing medical device shells, the first thing to do is to blanking them. When good blanking is achieved, the next process needs to be carried out. In this process, it needs to bend it. Bending accuracy can reflect the process accuracy of sheet metal processing and t…… MORE